The aircraft industry is among the most demanding in the world in terms of engineering and component quality. Any element of an aircraft, from turbines to hydraulic systems, must meet extreme safety and reliability requirements.

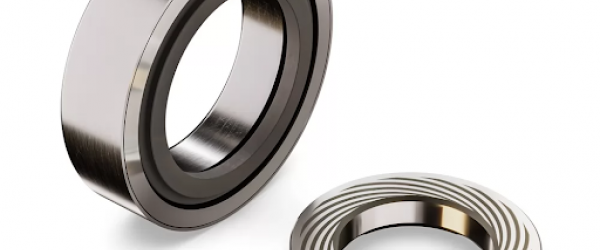

Mechanical seals, while often considered “secondary” components, are actually crucial to the safe operation of engines, pumps and auxiliary systems. Their design requires obsessive attention to detail because they must operate under varying and prohibitive operating conditions while ensuring maximum durability and minimum maintenance requirements.

Mechanical seals intended for aviation are critical components whose reliability must be absolute even under extremely demanding operating conditions. One of the main challenges is extreme temperatures: during flight, these can range from cryogenic values of less than -50 °C at high altitudes in the cruise phase to over 1000 °C near engines or auxiliary systems. Add to this the high pressures and intense thermomechanical cycles resulting from repeated switching on and off, inducing rapid expansions and contractions and continuously stressing sealing surfaces.

Reliability must be impeccable-there is no room for error, because a failure can compromise flight safety. This means that these seals must operate for thousands of hours without failure. In addition, they must be compatible with a wide range of special fluids, such as aviation fuels (Jet A, JP-8), high-performance oils and specific hydraulic fluids, without degrading or altering their properties.

Seals also operate under high-speed rotational conditions: in turbojets or compressors, speeds can exceed 100 m/s, with continuous vibration and axial and radial microdisplacement. In Air Turbine Starters (ATS) systems, speeds of 200 m/s are reached. As if that were not enough, there are stringent regulations to comply with, imposed by international certifying bodies such as the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency), which regulate the safety and traceability of materials. Finally, reduced maintenance requirements dictate designs that maximize service life and minimize the need for interventions during the life cycle of the aircraft.

To meet the challenges just mentioned, the materials used to make aircraft mechanical seals must combine light weight, dimensional stability, chemical and thermal resistance. The main materials used include:

These materials are chosen and combined according to the specific application environment, taking into account weight, durability and performance requirements.

Material selection for a mechanical seal in aviation is never a generic or standardized task. It requires in-depth, multidisciplinary engineering analysis.

One of the first factors to consider is operating temperature: for temperatures above 500 °C, superalloys, carbon or ceramic couplings are used, while tungsten carbide is ideal up to about 600-700 °C under dynamic conditions.

Chemical compatibility is equally crucial: materials must remain stable in contact with fuels, oils and hydraulic fluids (such as Skydrol), avoiding swelling, cracking or release of contaminants. Pressure and rotational speed also play a crucial role: seals must withstand high contact loads without permanently deforming, making hard, thermally conductive materials such as WC preferable.

Weight requirements cannot be neglected: every gram saved contributes to aircraft efficiency. Lightweight materials such as PEEK or ceramic composites are highly valued in this regard. Finally, reliability and certification are imperative factors: only materials qualified to military or aviation specifications (AMS, ASTM, EN) are used, with full documentary traceability and rigorous bench and in-flight validation testing.

In summary, the choice of the most suitable material is always the result of a customized design based on compatibility tests, stress tests, and thermofluid-dynamic simulations.

The choice of materials for mechanical seals in the aviation industry is not only a technical matter, but a guarantee of safety, reliability and durability.

In this context, we at Meccanotecnica Umbra, certified according to standard 9100, design and manufacture “build to spec” mechanical seals for the aviation sector, made with all key materials such as carbon, graphite, tungsten carbide, ceramics, superalloys and technical elastomers (including Viton®, Kalrez® and FEP). We are particularly known for manufacturing carbon seals, which offer strength, dry self-lubrication capabilities and high performance up to 600 °C. In addition, we offer “build to print” solutions, built to customer design, with some of the fastest lead times in the market.

For us at Meccanotecnica Umbra, each project is a unique engineering challenge, approached with expertise, experience and passion to ensure the highest level of quality and safety in flight. Contact us now for more information!

© 2026 - Meccanotecnica Umbra S.p.A.

Designed by Co.Mo.Do Comunicare Moltiplica Doveri

Developed by NUR Digital Marketing